3D printing can present all sorts of problems.Whether you are a newbie or expert, chances are you are constantly tweaking a bit here and a bit there just to get the desired results.There are, however, a number of things you can do to get around some common issues in 3D printing and improve your print quality. Good news is that you do not have to be an expert to get started.

Assembly & Set Up

Set up your 3D printer as per the instructions. No matter how experienced you are,your vendor supposedly knows the products better than you do. It is recommended that you use parts, software,and materials from the same brand wherever you can to get the best experience. Remember, every 3D printer has its own characteristics. Be open to some trial and error down the road.

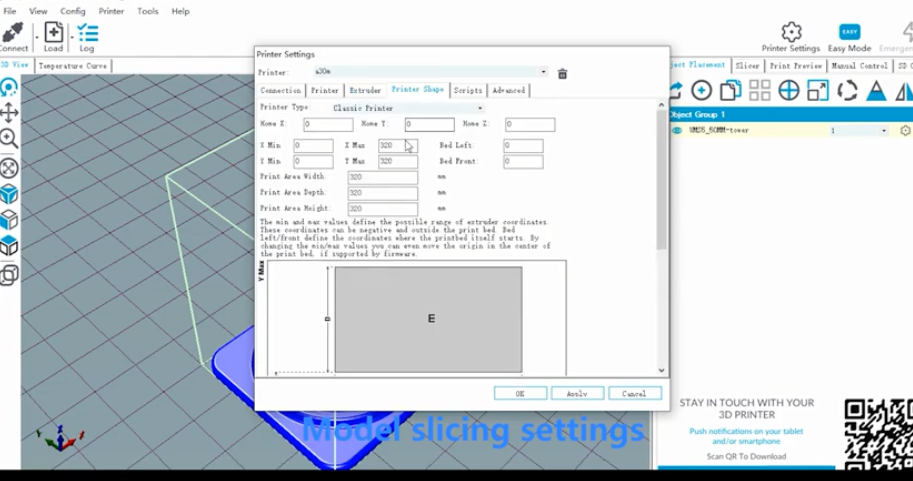

Software Update

Keep your system up to date. Manufacturers and slicer companies are constantly experimenting with their software and firmware to fix bugs and improve performance. If your machine features an automatic update, enable it.

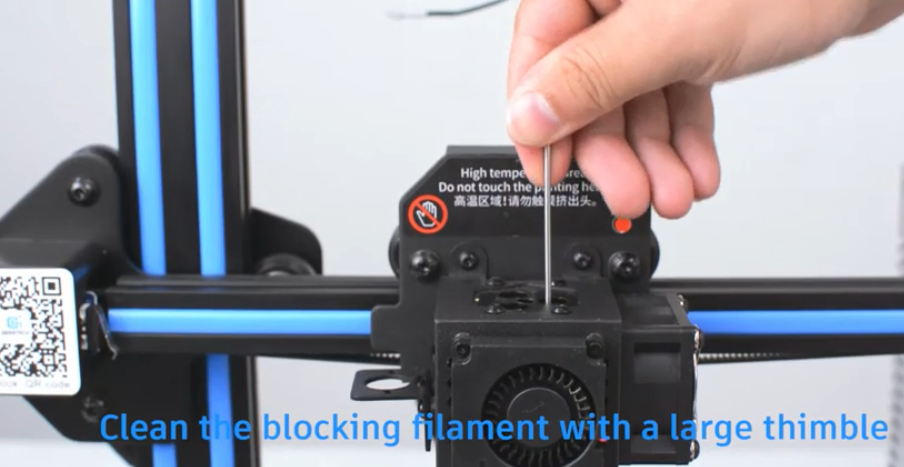

Maintenance

Perform regular maintenance and calibration on your 3D printer:form and maintain a routine of checks;keep your filaments from moisture and dust; calibrate the bed.

Supports

Bear in mind the 45-degree rule and 5mm rule. Any overhangs of above 45 degrees(or 60 degrees depending on your printer) may require supports. Just like overhangs, not all bridges require supports.Consider supports only when the bridge is more than 5mm long. “Rafts” , “brims” are great support tools to increase adhesion.Add support structures to your design for any steep overhanging features or models that have a small base.

While supports are great for some cases,you may want to avoid them,for the following reasons:first, it consumes extra filament; second, the print takes longer time; and finally, removing the support structure off the print can be a pain. If you are still not sure whether you need supports, run a test print to find out. You can also use your creativity to make the support structures part of your design, in case you think them necessary. Ways to circumvent supports: reorient your model; reduce the overhang angles;split your model into smaller parts.

The first layer

Your first layer is the foremost important layer of your print. Make sure it sticks well to the bed. Again, supports can be great tools to help with adhesion. Use a heated bed or apply glue to prevent warping from happening.

Details

Examine the details of your model. Are there any tiny projections or parts that are too small to print on a desktop 3D printer? In your printer, there is a very important but often overlooked variable, that is the line width, which is determined by the diameter of the printer nozzle. And most printers come with a nozzle of 0.4 mm or 0.5 mm in the diameter.