When you use a 3D printer to print everyday items, have you ever thought that you could even print an organ of your own body?It’s hard to believe, but it happens.That’s what CollPlant Biotechnologies and United Therapeutics Corporation are looking to do: they have just expanded their collaboration to 3D bioprinting of human kidneys for transplants.

Currently, more than 100,000 people in the United States are waiting for organ transplants.Kidney patients account for most of the demand, with more than 90,000 people seeking donor organs.Statistics show that 17 people die each day while waiting for new organs.At the same time, a new patient is added to the waiting list every ten minutes.So the American company United Therapeutics paid the Israeli company CollPlant 3 million dollars to speed up the production of the famous Bioink, called rhCollagen.This will provide ideal characteristics for bioprinting, including optimal rheology, greater safety, bio-compatibility and adjustable physical properties.It can also be compatible with a variety of technologies such as extrusion, inkjet or stereolithography.

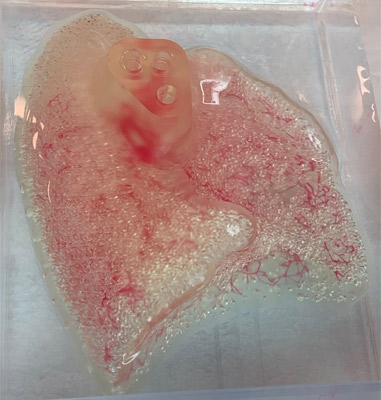

Bio-printing is a particularly interesting technology for the medical sector, allowing the creation of human tissue and treatments that is suitable for each patient.Every day, methods are evolving and innovations are emerging, which means we’re sure to see functional organs being 3D printed within a few years.The good news for those waiting for transplants is that Bioprinting can design livers, pancreases, spleens and even kidneys.The companies CollPlant Biotechnologies and United Therapeutics Corporation have recognized that this technology could be the future of tailor-made medicine.

In October 2018, the two companies began a collaboration: United Therapeutics received an exclusive license for the CollPlant technology to produce and use bioinks based on human collagen for bioprinted lung transplants.Two years later, the partners began working on a kidney, an organ in need of a donor.CollPlant Bioink is made from human collagen.It requires very strict purification conditions, which makes it extremely long to process, but most importantly it is difficult to produce on a large scale.So the Israeli company relies on a plant platform to produce collagen.They explain: “The production of our recombinant human type I collagen (rhCollagen) starts in genetically modified tobacco plants. The recombinant human protein in the form of ‘procollagen’ is extracted from the leaves of mature plants and processed to produce a highly purified rhCollagen that can be used for the production of medical products.” This innovation will help develop bioprinting and regenerative medicine, provide an opportunity to create quality bioinks for the eventual design of different types of organs.

Thanks to the attention paid by the American United Therapeutics Corporation,the manufacture of kidneys is being addressed in hopes of reducing the number of patients waiting for transplants.

Reference:https://www.3dnatives.com/en/collplant-united-therapeutics-kidney-bioprinting-051020204/#!

没有评论:

发表评论